SUCCESS STORIES

At Amapex Environment, we have achieved excellent results with the application of our biotechnology solutions in the following industrial sectors, achieving results with a significant economic and environmental impact.

OUR FEATURED PROJECTS

Textile

TEXTILE INDUSTRY-PRINTS

Success Story in the province of Girona, Spain

Customer

Printing factory that offers its services to one of the largest retail and distribution chains of fashion textile products in the world.

Challenge

550 m3/day of industrial wastewater from the production process.

Results

Reuse of recovered water in the production system.

Savings in total water consumption costs and external treatment costs.

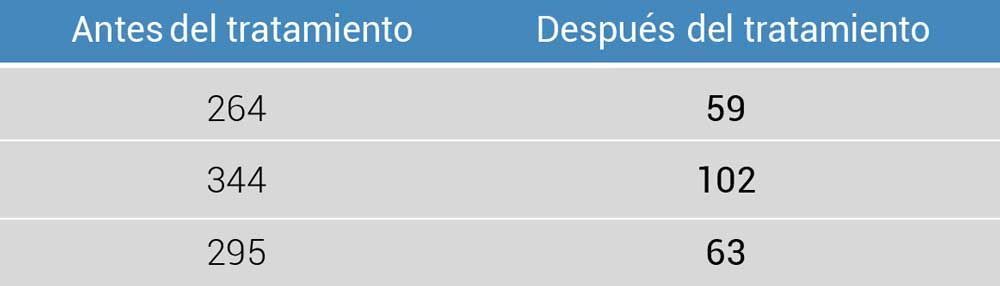

Ammonium Concentration (ppm)

Customer need

- Industrial wastewater treatment as a byproduct of the printing of all types of fabrics, which produces 550 m3 of wastewater per day.

- 50% reduction in ammonium levels present, originating from chemical additives used in dye fixation.

- Reduction in the color of the resulting water after treatment.

- Reduction in the consumption of mains water used throughout the production process.

- Cost reduction in the external purification process.

The solution

Amapex has designed a customized biotechnology solution for this industry, which lacked its own treatment system. Using existing homogenization facilities, we reduced the contaminants analyzed by the external treatment plant for subsequent collection, thus reducing costs.

We allow the reuse of a percentage of the water required for the operation of the fiber filtration system before sending the effluent to the treatment plant, thereby reducing the flow rate required for treatment and also lowering the cost of external treatment.

The system involves treating industrial wastewater, with the intervention of a third party, with a custom-designed mixture of bacteria and nutrients. Using the Smart Doser Unit, a system that allows the implementation of a biological system (in this case, nonexistent) and also monitors the entire treatment process, we achieve accelerated bacterial reproduction.

The use of this innovative system allows for greater efficiency in eliminating pollutant loads and saves on the use of complementary techniques, such as carbon filters, ozonation, and others, which are costly and require frequent replacement.

Applications

This Amapex solution is specifically designed for the treatment of wastewater from the textile industry and can be successfully applied in dry cleaners, textile finishing companies, and wastewater treatment plants for various production processes within the sector.

Petrochemical

ELASTOMER INDUSTRY

Success stories in Lombardy, Italy

Customer

Multinational company manufacturing elastomers for thermal and acoustic insulation.

Challenge

Production of high emissions of toxic gases to the outside, with high concentrations of chloroparaffins as a result of the manufacture of elastomeric insulators.

Results

Elimination of 96% of toxic polluting gases. 90% reduction in treatment costs.

Before and after water purification treatment with Amapex solution

Customer need

- Purification of toxic gases emitted to the outside, with the aim of reducing the concentrations of chemical substances contained mostly in chloroparaffins.

- Reduce the high costs estimated at €1,200,000/year of the current conventional gas purification system, based on filters and chemical neutralization processes.

- Eliminate the risk of the proliferation of hazardous emissions to the surrounding population.

The solution

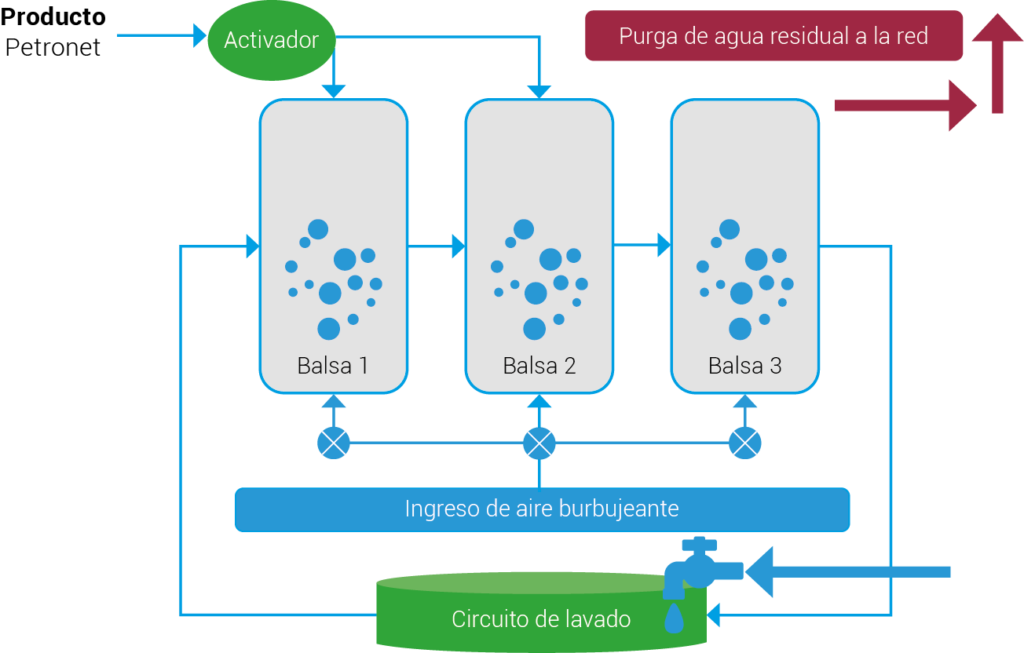

The solution consisted of replacing the toxic gas purification system with a gas scrubbing system, combined with an AMAPEX biological solution that eliminates polluting toxic gases and significantly reduces the high costs of the previously used cleaning system.

Gas washing is carried out by passing the gases through a chamber of cold plates that condense the vapors over a circulating water tank.

Once the gases are liquefied, dissolved or dispersed in water, the water is treated.

The system involves applying a solution containing a mixture of bacteria and nutrients specifically designed for each client. The bacteria activate very quickly and effectively, metabolizing the contaminants present in the water.

For bacterial multiplication, an intelligent unit has been designed that, by reading the parameters of the water to be treated, activates the biological mixture to provide it with optimized activity.

Applications

This AMAPEX solution can be successfully applied in any elastomer, technical rubber, or similar manufacturing plant that emits toxic polluting gases to the outside.

Textile

TEXTILE INDUSTRY

Case of Exit in Chieri (Piedmont), Italy

Customer

Textile dyeing and finishing factory for cotton and synthetic fabrics.

Challenge

150 m3/day of industrial wastewater to be treated from the washing of previously dyed textile pieces.

Results

Reduction of pollutants that allows for the reuse of 60% of the water emitted. Savings of 60% in total water and treatment costs.

Before and after water purification treatment with Amapex solution

Customer need

- Purification of industrial wastewater as a byproduct of the industrial dry cleaning process, which produces 150 m3 of wastewater per day.

- Elimination of high levels of contaminants present in industrial waters, which contain significant amounts of oils and greases from the use of textile dyes, in addition to other chemical elements from the fixing and dyeing process.

- Decolorization of wastewater heavily contaminated by the dyes used in dyeing.

- Reduction in the consumption of mains water used in the production process.

- Reduction of materials and subsequent filtering techniques.

- Reduction of the sanitation fee corresponding to discharges into the public network.

The solution

The Amapex solution, custom-designed for the existing water treatment system, simplifies the wastewater treatment process.

The system consists of treating wastewater with a solution containing a mixture of bacteria and nutrients specifically designed for each client.

The bacteria reproduce very quickly, acting effectively in eliminating the contaminating compounds present in the treated water.

To activate the bacteria, an intelligent unit has been designed that, by reading the parameters of the water to be treated, activates the biological mixture to provide it with optimized activity.

The use of the system, in addition to greater efficiency in eliminating the pollutant load, saves the customer from having to use complementary techniques such as carbon filters, ozonation, and others, which are expensive and require frequent replacement.

Applications

This AMAPEX solution is specifically designed for wastewater treatment in the textile industry and can be successfully applied in industrial dye houses, textile finishing plants, and tanning treatment plants.

Petrochemical

CHEMICAL INDUSTRY

Success Story in Tarragona (Catalonia), Spain

Customer

Industry specialized in chlorine chemistry.

Challenge

3,000 m3/day of industrial wastewater to be treated from the production of fertilizers, insecticides and pesticides.

Results

Lindane reduction of over 95%. Cost savings of 70% compared to traditional industrial wastewater treatment systems.

Customer need

- Purification of industrial wastewater from the manufacture of fertilizers, insecticides, and pesticides.

- Elimination of high levels of organochlorine contaminants present in wastewater, especially Lindane (>7900 ng/l), which is highly toxic and very difficult to eliminate.

- Reduce the cost of conventional water treatment methods, which amounts to more than €150/m3.

The solution

A customized AMAPEX solution that reduces the lindane content of treated water, significantly reducing costs compared to traditional wastewater treatment systems.

The solution consists of treating contaminated water by passing it through retention tanks, applying a solution containing a mixture of bacteria and nutrients, specifically designed for each client.

The bacteria activate very quickly and efficiently, metabolizing organochlorine compounds present in the water with particular efficiency.

For bacterial multiplication, an intelligent unit has been designed that, by reading the parameters of the water to be treated, activates the biological mixture to provide it with optimized activity.

Applications

This AMAPEX solution is specifically designed for wastewater treatment in the chemical industry and can also be successfully applied in the plastics and styrene industries, and in general, in all petrochemical-derived industries with high production of wastewater containing chlorinated effluents.

Liked

TANNING INDUSTRY

Success Story in Barcelona (Catalonia), Spain

Customer

WWTP (Wastewater Treatment Plant)

Challenge

More than 2,000 m3/day of industrial wastewater from various tanneries in Barcelona.

Results

Approximate reduction of 92% in COD and 52% in NH4+. 50% reduction in the current cost of the water treatment system.

Customer need

- Purification of industrial wastewater as a by-product of leather tanning.

- Elimination of high pollutant loads, composed of liquid chemical waste containing ammonium, dyes and mineral salts.

- Disposal of solid organic waste of animal origin, containing fats, skin and hair remains.

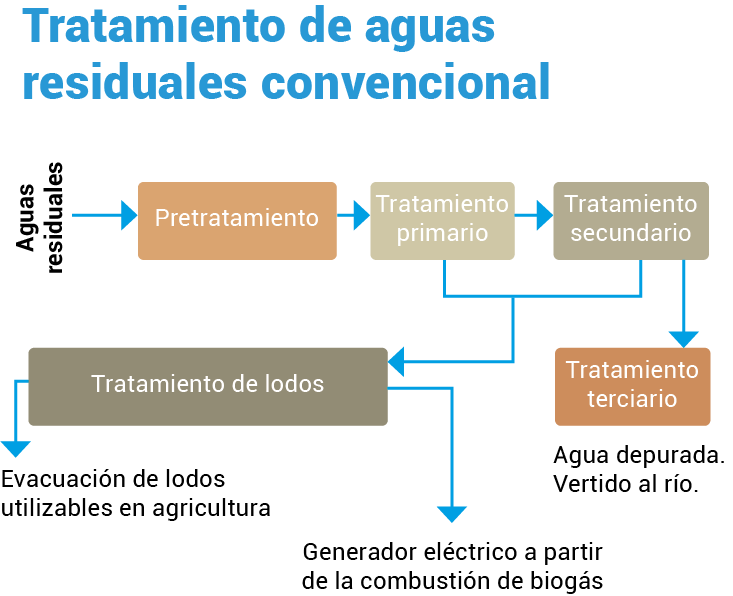

- It involves combined physical-chemical and biological water treatment.

The solution

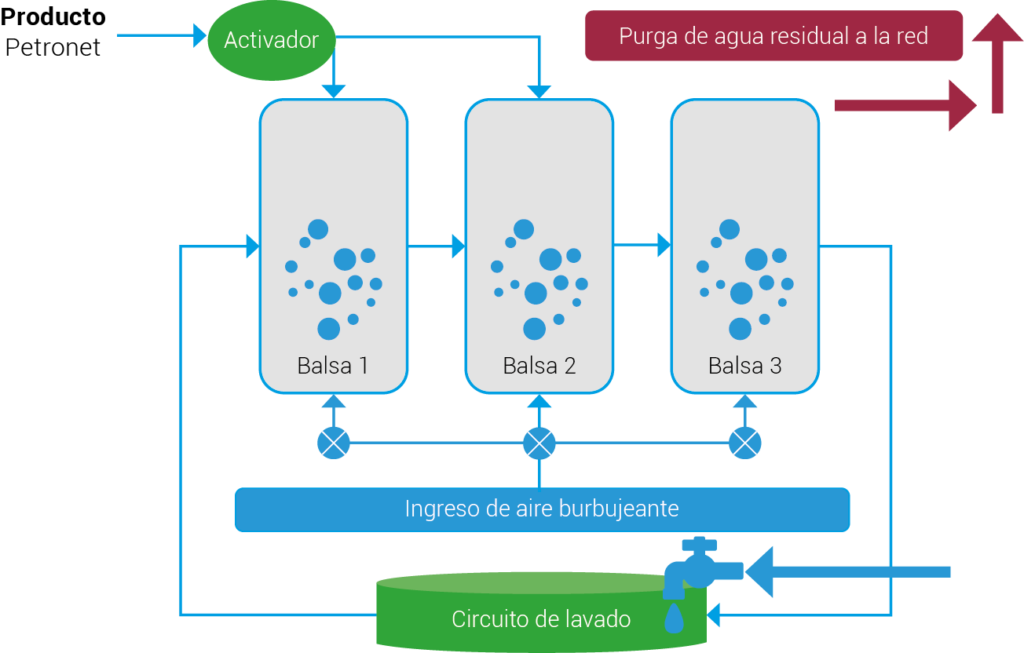

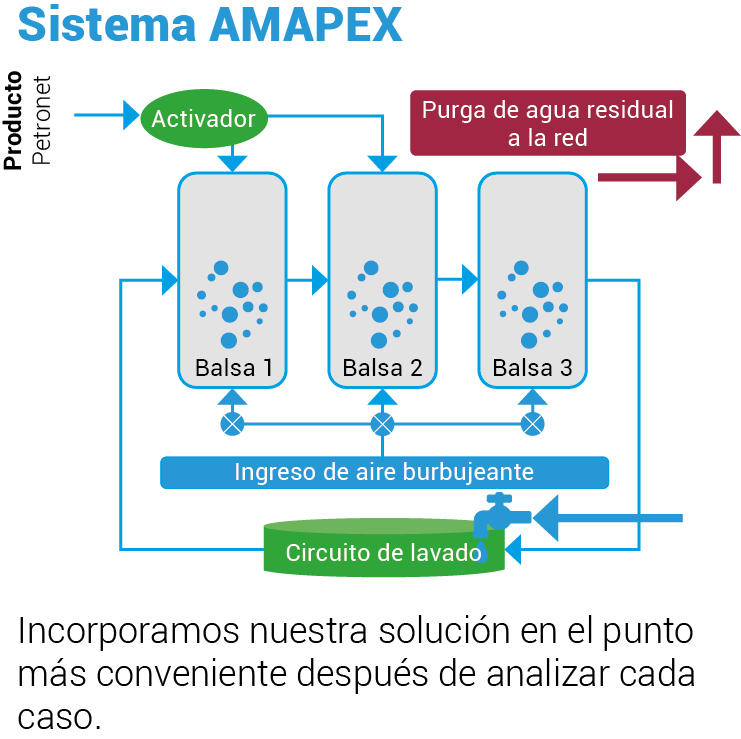

A custom-made AMAPEX solution for the current effluent treatment process that achieves similar results in reducing the Chemical Oxygen Demand (COD) and Ammonium (NH4 ) of treated water, with a significant cost reduction compared to traditional wastewater treatment systems.

Depending on the process applied and the client's needs, the AMAPEX System can be proposed as an alternative to the current purification system or as a complement to it.

In this specific case, the results correspond to total replacement and essentially involve the introduction of a mixture of bacteria and trace elements into the treatment ponds.

These bacteria and trace elements have been previously activated in a smart reactor, designed by Amapex.

The results in terms of contamination parameters are better than with the conventional system, after 3 days of treatment and at a cost less than 50% of the current cost.

Each case must be studied in detail, due to the wide variability of water treatments performed in tanneries, depending on the type of hides and their intended use.

Applications

This AMAPEX solution is specifically designed for treating wastewater in tanneries and can also be successfully applied in treatment plants that collect wastewater from various leather processing operations.

Metal - mechanical

METAL-MECHANICAL STAMPING INDUSTRY

Case of Exit in Santena (Piamonte), Italy

Customer

Metal casting and stamping factory.

Challenge

15 m3/day of industrial wastewater as a residue from the metal washing and lubrication system process for casting and stamping

Results

Reduction of more than 56% in COD. 50% reduction in oil and fat content. The proposed treatment system represents less than 50% of the current treatment cost. It allows for treatment at the client's premises without the need for external waste management services.

Customer need

- Treatment of wastewater with high levels of toxic and corrosive contaminants, resulting from metal smelting and stamping.

- Reduction of high concentrations of oils and fats exceeding 3,000 mg/l.

- Reduction of Chemical Oxygen Demand (COD) exceeding 25,000 mg/l.

- Reduction of the high costs of complex wastewater treatment services, which amount to more than €120/m3 for the removal and disposal of contaminants.

The solution

Direct application of the customized AMAPEX system, which consists of treating contaminated water by passing it through retention tanks and applying a solution containing a mixture of bacteria and nutrients, specifically designed for each client.

The bacteria activate very quickly and efficiently, metabolizing the polluting compounds present in the water (oils, fats, surfactants and metals) with particular efficiency.

To activate the bacteria, an intelligent unit has been designed that, by reading the parameters of the water to be treated, activates the biological mixture to provide it with optimized activity.

Applications

This AMAPEX solution is also successfully applied in the screw and technical metal parts production industries, which use large quantities of water and oil for process cooling and lubrication.

Metal - mechanical

METAL-MECHANICAL MOTOR INDUSTRY

Success Story in the South of the Netherlands

Customer

Factory of components for wind turbine engines

Challenge

10 m3 of industrial wastewater per day to be treated as a by-product of cooling and lubricating the components for wind turbine engines.

Results

Reduction of more than 60% in the current cost of wastewater treatment. Reuse of 70% of treated wastewater. Potential reuse of 80% of oils for lubricating purposes.

Separation of water and oil after applying Amapex biological solution

Customer need

- Purification of industrial wastewater with a high content of special oils and other chemical components, resulting from the use of "Cutting Agents," emulsions of water with special oils used as coolants and lubricants.

- Reduction of the high annual costs of wastewater treatment, which amount to around €200/m3.

The solution

Direct and customized application of the AMAPEX biological system, which consists of separating the oily and aqueous phases for the purpose of reusing them.

The contaminated water is treated by passing it through retention tanks, where a solution containing a mixture of bacteria and nutrients, tailored to each client, is applied.

The bacteria activate very quickly, effectively eliminating contaminants present in the water (oils, fats, surfactants, and metals).

To activate the bacteria, an intelligent unit has been designed that, by reading the parameters of the water to be treated, activates the biological mixture to provide it with optimized activity.

The water can be reused in the same factory and the oil could be reused for lubricating purposes without special requirements.

Applications

This specific AMAPEX solution can also be successfully applied in engine factories and in automotive repair shop waste collection centers.

Metal - mechanical

Biogas production

Success Story in Ottawa, Canada

Customer

Engineering company manufacturing anaerobic biogas plants.

Challenge

Improving biomethane production results in the anaerobic digestion of lignocellulosic matter.

Results

Increase in biomethane production by 10%.

30% reduction in maintenance

Customer need

- Achieve biodigestion of products with a high amount of cellulose, such as pruning waste.

- Reduce biodigestion time by increasing the glucose available in the process.

- Reduction of process-associated gases (H2S and NH4*) with harmful effects on power generation engines and the digesters themselves, improving biogas quality.

The solution

The solution consisted of applying a biological pretreatment specifically designed for the material to be biodigested (wood pellets from pruning) with the aim of breaking down the cellulose chains before entering the biodigester.

This provides the glucose needed for biogas production with a higher concentration of biomethane.

The genetically selected bacteria used in the pretreatment, in an anaerobic situation, use ammonia to "breathe," reducing its presence in the biodigester, improving efficiency and reducing maintenance.

For bacterial multiplication, an intelligent unit has been designed that, by reading the parameters of the material to be digested, activates the biological mixture to provide it with optimized activity.

Applications

This AMAPEX solution can be successfully applied in any anaerobic digestion biogas generation plant, both to improve production and to purify it.

CONTACT US

HEADQUARTERSAmapex Environement SLCarrer Rocafort 240, entlo 3 08029Barcelona931 597 479 | 617 509 430

www.amapex.netjoaquimcanadell@amapex.net

Olot Road 24, 17856, Castellfollit de la Roca, Girona.

Contact form

Cando08037, Barcelona, Spain.candowaste.com